Materials Science

Whether specifying materials for instrumentation lines, hydraulic power, chemical injection, deluge systems, or other demanding applications, special attention should be given to managing corrosion. Just about every metal corrodes under certain conditions, but with proper materials selection the threat can be minimized.

At Swagelok Minnesota | North Dakota | Appleton, we help simplify the selection process with our deep understanding of factors that contribute to corrosion, as well as the special properties of materials that help fight it. As a supplier with a diligent focus on proper materials selection, we provide:

- Products using alloys with at least two different elements in optimized concentrations to give superior corrosion resistance.

- A deep understanding of corrosion and suggestions for controlling its impact on your fluid systems.

- Materials Science training opportunities. These courses are designed to help fluid system professionals select components comprised of the right materials to provide long-lasting performance in challenging end-use environments. Review course information.

- Confidence in quality control measures, which include a dedicated Raw Materials Facility, non-destructive testing, and thorough sampling for internal or surface defects.

Take a virtual tour of our Corporate Raw Materials Facility and see where our quality begins.

When you can visually identify corrosion and know where to look for it, risks to your fluid system can be minimized. Better yet, when engineers can anticipate corrosion and make the best choices, system integrity, longevity of assets, performance, and safety can all improve. You can take these steps to reduce the impact of corrosion on your applications:

Identify

Identify different types of corrosion, their causes, and where they commonly occur.

Minimize Corrosion Risks

Minimize corrosion risks by reducing crevice sites, avoiding dissimilar metal contact, and selecting resistant materials.

Specify Proper Components

Specify proper components, including tubing, supports, and clamps, to enhance corrosion prevention.

Stay Informed

Stay informed on industry standards and best practices through training and other resources.

Identifying Corrosion

Corrosion is the physical degradation of a material due to interactions with its environment. It occurs when a metal atom is oxidized by a fluid, which leads to a loss of material in the metal surface. Corrosion reduces the surface's thickness and makes it more prone to mechanical failure.

Do You Have Rust?

Rust appears when you have carbon steel corrosion. This occurs when iron corrodes and forms iron oxide. Many other types of corrosion exist, however, that can threaten your application. Understanding the different types of corrosion can help in your material selection process.

Types of Corrosion

- General (Uniform) Corrosion

- Localized Pitting Corrosion in Chloride-Containing Media

- Localized Crevice Corrosion in Chloride-Containing Media

- Sour Gas Cracking or Sulfide Stress Cracking at High Hydrogen Sulfide (H2S) Partial Pressure

- Hydrogen Embrittlement

- Intergranular Corrosion

- Stress Corrosion Cracking in Chloride-Containing Media

- Galvanic Corrosion in the Presence of an Electrolyte

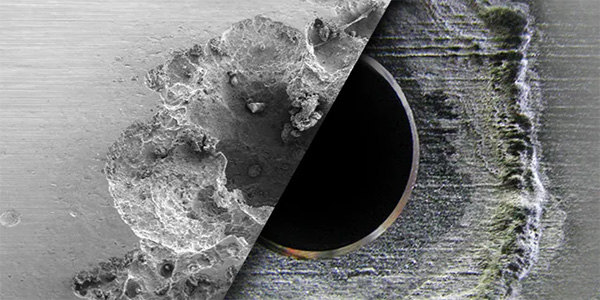

Pitting Corrosion vs Crevice Corrosion

Read this article to gain a better understanding of two forms of localized corrosion in stainless steel: pitting and crevice corrosion.

Corrosion Resistant Metals

Selecting the right material for all of the numerous components used in an application isn't easy. Fortunately, our products give you the options you need for greater resistance against each corrosion type. Learn more about each metal, and our high standards for their use in our products:

High Quality Components Made from Corrosion Resistant Metals

To maintain a reliable, safe, and efficient fluid system, you need superior raw materials combined with manufacturing excellence. Our products are designed to stand up to the demands of challenging operating environments across a wide variety of industries. You'll appreciate the quality that comes from Swagelok and its components. Consider all of the options we offer for our product lines so you can select the right component.

Requirements and Standards

If you need to adhere to the NACE MR0175/ISO 15156 sour gas standard, Swagelok fluid system components made from either 316/316L or special alloys meet the requirements... Read more.

To support NORSOK standards, we can quote orders for tube fittings, pipe fittings, and select general industrial valve products manufactured from NORSOK-certified material... Read more.

Materials Science Training

Regardless of your industry or application, a strong understanding of materials science is invaluable. Let us help you get there through detailed training conducted by a materials science expert. Attend a Swagelok® Materials Science Training course to learn:

- How to select components comprised of the right materials

- How specific alloys resist corrosion

- How materials behave, and how industry standards impact your material choice